Vibro Media

Mass finishing is a process that automates the mechanical and chemical finishing of parts. The benefits of this stage in the manufacturing process of components are cost and time savings, as it allows large numbers of parts to be finished simultaneously.

Mass finishing can be used for a variety of applications, such as deburring, removal of machining lines and superfinishing in many industries including medical, automotive, and aerospace.

![]()

Finishing Media

The range of Master finishing consumables has been developed to provide the desired finish for various applications. This product category includes Master Agro, Pre-treated, Plastic, Ceramic, and Special Media, all to suit the numerous challenges in different industries.

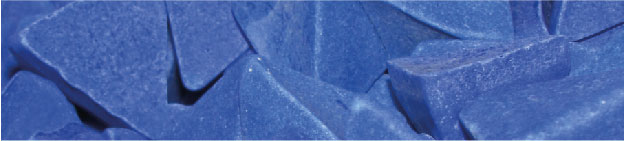

Ceramic media

Ceramic media is suitable on harder materials for applications such as deburring, grinding, edge radiusing, and polishing. Master ceramic media is available in a range of different abrasive grades and geometries, such as Triangle Angle Cut in grades low cut to super finish.

Plastic media

In comparison with ceramic media, plastic media is well suited on softer materials. Suitable applications include deburring, grinding, smoothing, and producing a matte or pre-plate finish. Due to its composition, this media keeps its shape as it wears down. Master plastic media is offered in different abrasive grades and geometries, including cones in grades fine cut to medium fine.

Agro (dry) media

The range of Master agro media includes corncob and walnut shell, both being manufactured in various sizes to suit part geometry. Corncob is a great product for drying, cleaning and polishing, while the walnut shell produces a bright polished finish due to its hard and fibrous grain. Both corncob and walnut shell can be supplied in a pre-treated form to achieve a mirror finish or to impart high lustre on components. All Master agro media products are bovine-free.

Special media

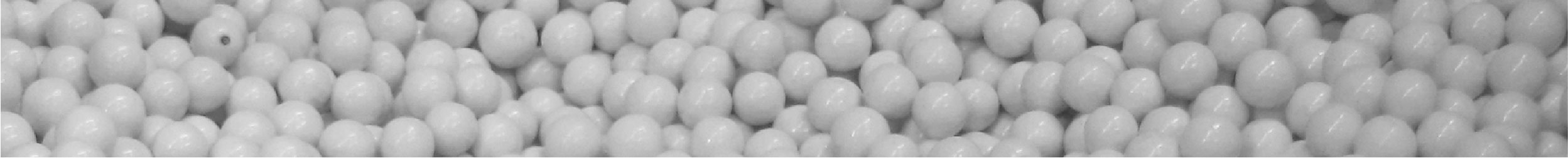

Master also offers a range of special media which includes stainless steel media, wood media, special plastic media, aluminium oxide, and separating ball media.

Stainless steel media is ideal for burnishing and light deburring parts and we supply this media in different sizes and shapes such as balls, ball cones and pins.

Some applications for special plastic media include achieving a low surface finish on medical implants, removing machining lines, grinding, and polishing. This media can be used to finish parts manufactured out of cobalt chrome, stainless steel, non-ferrous materials, and semi-precious and precious metals.

Aluminium oxide is an abrasive and durable media which can be recycled, making it a cost-effective finishing solution. This media is great for blasting, grinding, polishing, edge rounding, achieving a matt finish, cleaning and preparing part surface for plaiting or painting. Due to its light composition, there is a low chance of parts being damaged in the finishing process.

The separating ball media has been developed to keep flat parts separate while being processed ensuring components do not stick to each other.

Compound

Our environmentally friendly and biodegradable compounds have been formulated to suit a variety of applications such as corrosion inhibition, descaling, cleaning, degreasing, polishing or burnishing. We offer liquid compounds, vital to the cleaning and finishing process, as well as powders and pastes which contribute to the grinding and polishing of materials.

We recommend using our compound along with our media as it acts as lubricant thus extending the media life. Our extensive range of compounds has been developed for both ferrous and non-ferrous parts.

Contact us for technical application support advice on mass finishing vibro media and compounds.