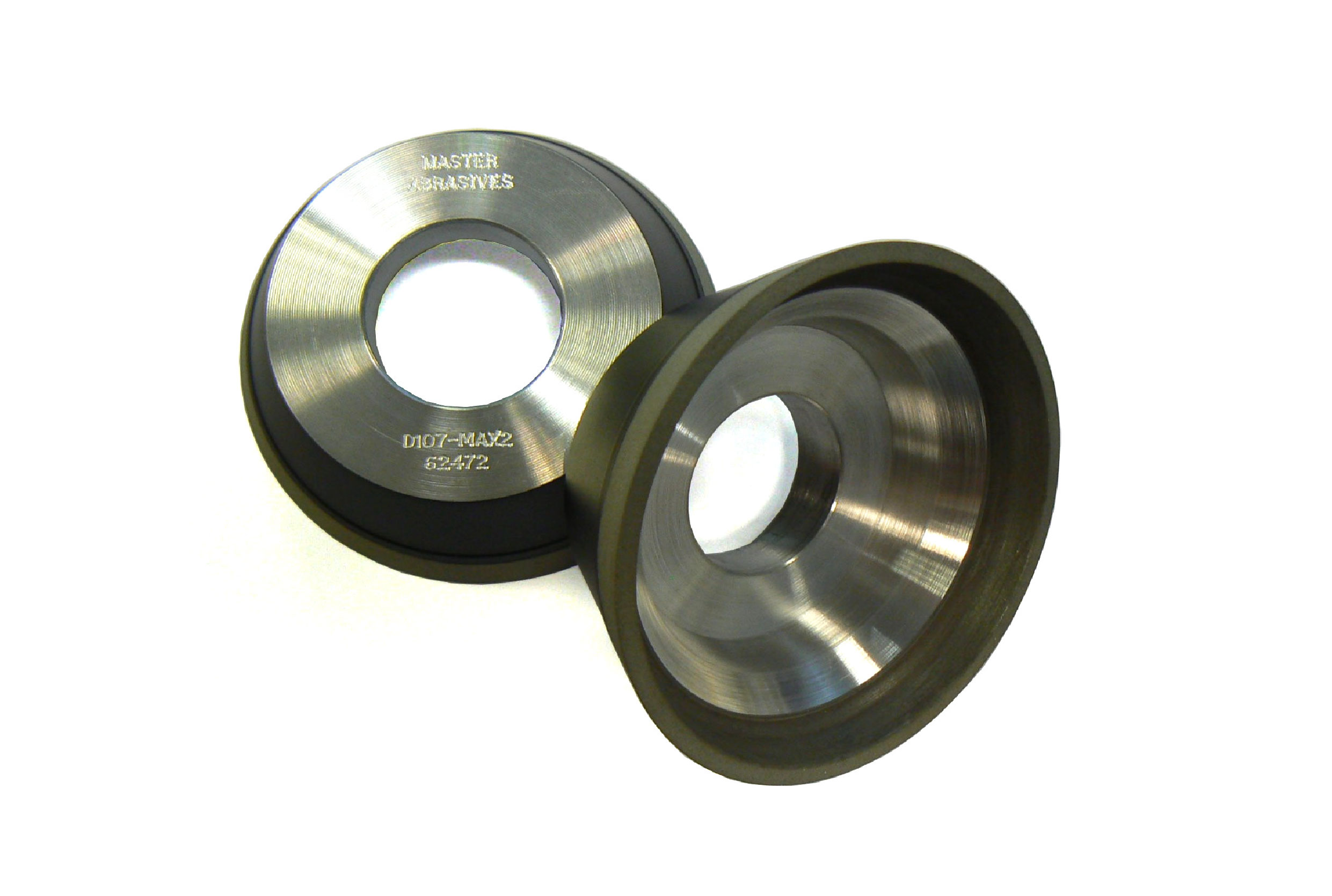

Resin Bond

This bond uses phenolic or polyamide resins to hold the CBN or Diamond in place. Wheels manufactured by this method are reasonably free cutting although they may have to be kept open by the use of an aluminium oxide stick, which periodically has to be pushed into the rotating wheel. These wheels are extremely popular for tool and cutter manufacturing and re-grinding.

![]()

We offer phenol and polyimide resin bonded products in both diamond and CBN to suit the grinding and finishing applications. This product range is available in all FEPA standard shapes as well as specials to suit your specific requirements.

They can operate either with or without coolant, as it is possible to add lubricants to the resin bond formulation. Variations in the bond hardness can also be achieved by use of differing bonds.

For optimum performance this product should be engineered to suit the individual application. Resin wheels have to be trued and then have a separate dressing operation carried out, often by hand.

All our resin bond wheels are available on either Aluminium or black Bakelite bodies.

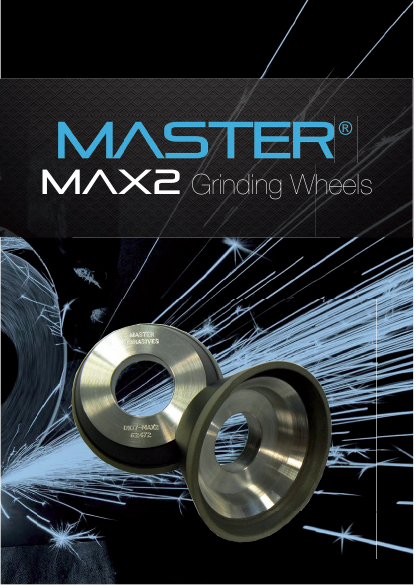

MAX2 Grinding Wheels

MAX2 is a resin bond designed for use in the tool and cutter grinding market. Utilising the latest technology, the cool cutting action and long lifetime make MAX2 a leading alternative to other manufacturer’s wheels, offering excellent performance and value for money in dry grinding conditions.

Availability

MAX2 wheels are available in both CBN & Diamond.

Features and Benefits

- Cool cutting action

- Long lifetime

- Excellent performance

- Value for money

Applications

- Re-grinding flutes

- OD relief

- Primary & secondary relief

- Point sharpening

- Applications in steel or carbide

Wheels for grinding thermally applied coatings

The increased utilisation of thermally applied coatings (e.g. HVOF, plasma spray, etc.) which are very tough and wear resistant has lead Master to introduce a specific range of resin bonded diamond wheels to meet the grinding requirements.

Stripping Wheel

Coarse Diamond grit wheel designed to cope with the demands of removing an old coating and grinding the softer base substrate. Micro-lubrication and micro-porosity bond technology is utilised to offer fastest possible stock removal rates, without excessive wheel wear when grinding the softer base substrate.

Combination Wheel

All round specification designed to strip off the old coating and grind the full range of new thermally applied coatings. Medium sized Diamond grit gives a good commercially ground finish.

Finishing Wheel

Dedicated wheel designed primarily for grinding just the thermally applied coating. Fine to medium Diamond grit sizes give a very good surface finish.

Dressing the wheels

Master dressing stones are available for the general dressing of Diamond and CBN abrasive wheels including, cleaning, opening and reshaping.