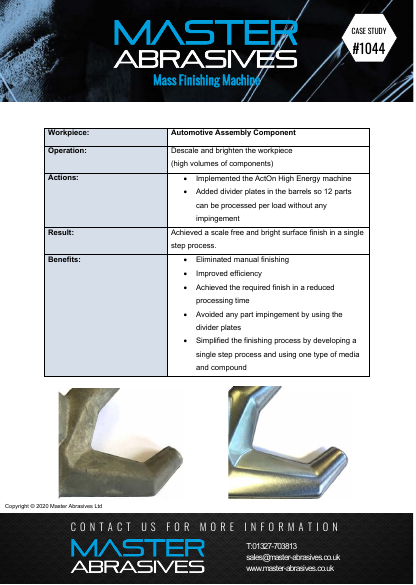

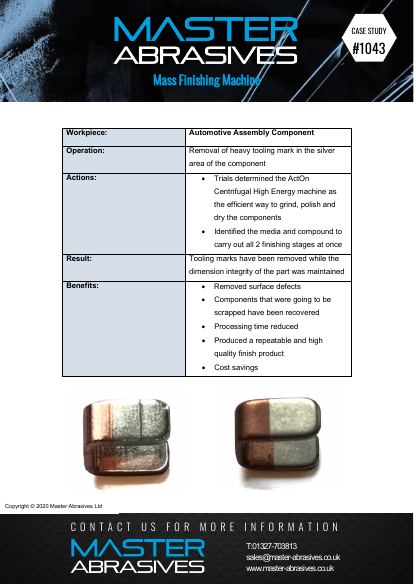

Centrifugal High Energy

In many cases, the results achieved via Centrifugal High Energy Finishing cannot be achieved in a standard vibratory process. Particularly applications that include achieving a high surface finish requirement, a mirror finish and the removal of heavy manufacturing defects. Parts that require hand finishing are excellent candidates for High Energy Finishing.

One of the main advantages of CHE Finishing is the reduced processing times for most applications. These machines can be 10 times faster than vibratory finishing, producing superior finishes.

Key Features:

- Removable barrels

- Easy and quick barrel changeover

- Removable liners

- Pressure release valves on barrels

- Safety feature: door interlocking safety switch provided

- Manual load and unload

- Very quiet machine in operation

Contact us for more information or to speak to a technical sales representative who can assess your mass finishing requirements.

Further Resources

To complement ActOn Finishing machines, we offer a full range of Master finishing consumables – see our product page for more information.