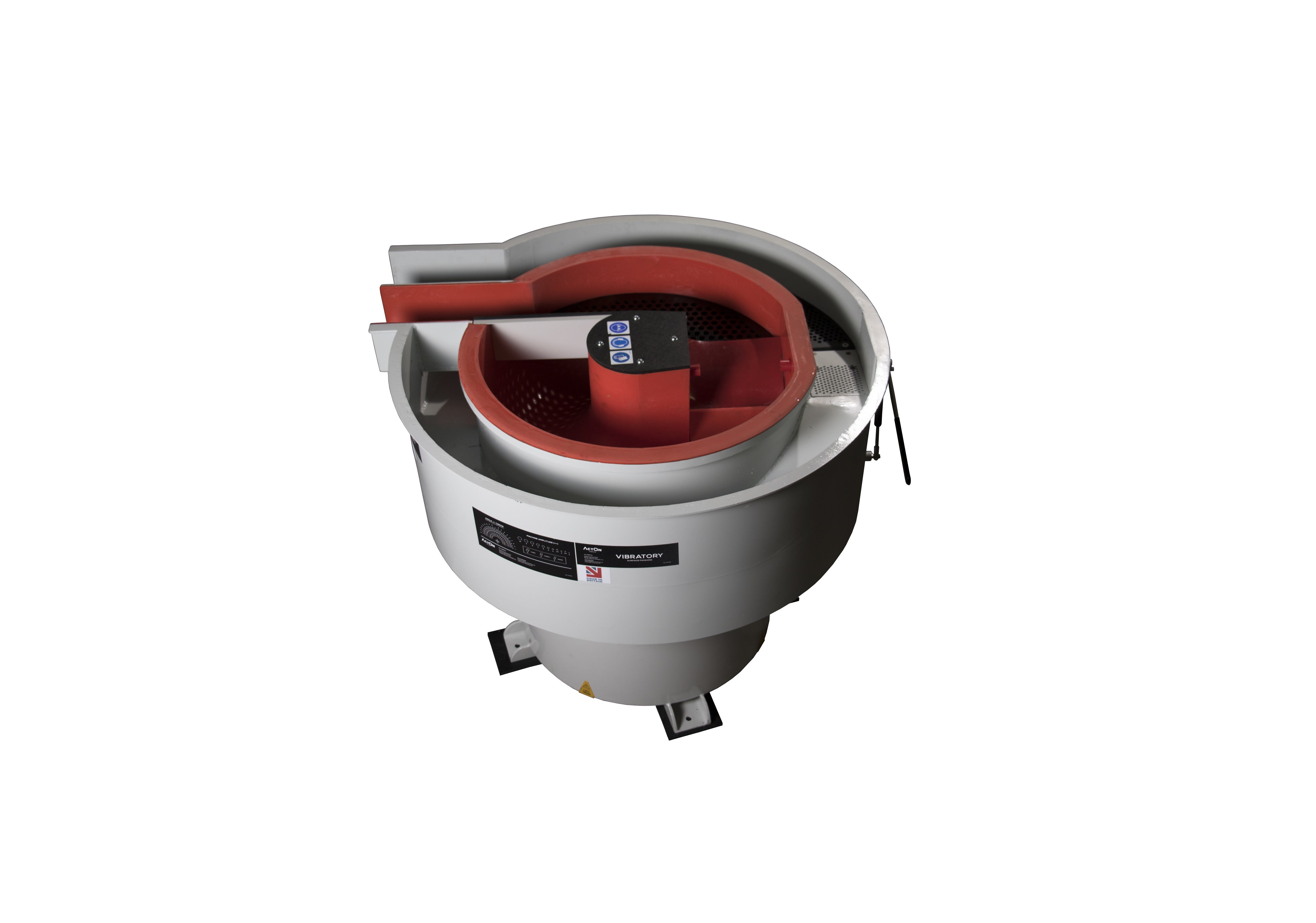

Dual Finishers

The orbital Dual finisher works to both deburr and dry in one single unit, an excellent and economical finishing option.

The design of the Dual Surface Finishing machine integrates two process chambers: an inner chamber that can be used for wet process application, and the outer chamber for dry process applications, both of which make it easier to control.

While the inner chamber can be used from deburring, descaling, radiusing, surface finishing and cleaning to polishing and surface improvement, the heated outer chamber can be used for drying or cleaning the parts after being processed in the inner chamber. This is both an excellent and economical finishing option.

Key Features:

- Process bowls stress relieved to improve life

- Design ensures ease of customisation

- Removal of screens with our wedge type locking system reduces down time

- Spray bar with nozzles over the separation screen can be used to clean the parts prior to discharge from the machine

- Ergonomical and easy to use

Further Resources

To complement ActOn Finishing machines, we offer a full range of Master finishing consumables – see our product page for more information.